Efficiency - Innovation - Optimization

Caden not only designs new tools and machines but also maps out existing machines. Our engineering projects address mechanical challenges across various sectors, from pharmaceuticals and chemicals to heavy lifting and traditional machinery. In everything we do, we strive for high-quality designs and technological innovation.

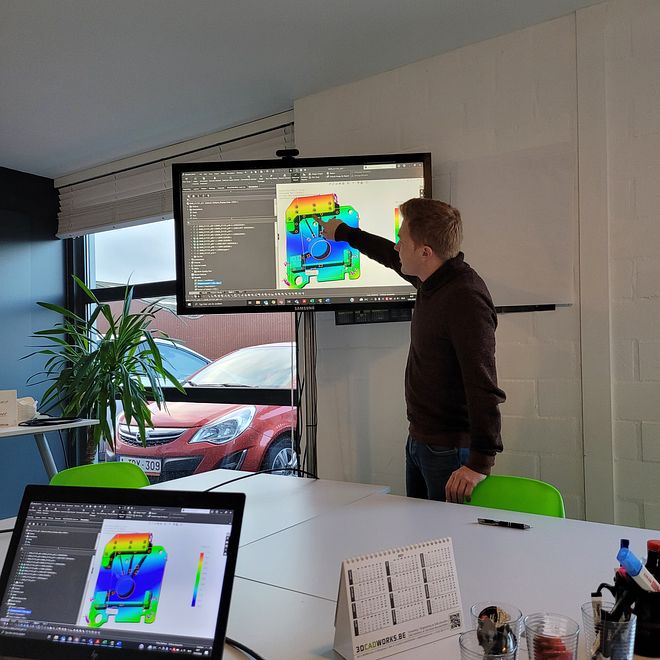

Knowledge-based engineering

Rely on Caden's knowledge and skills for all your engineering needs, CAD drafting work, or for improving your machine safety. We can also digitize a product line to support your sales team with presentations on a tablet.

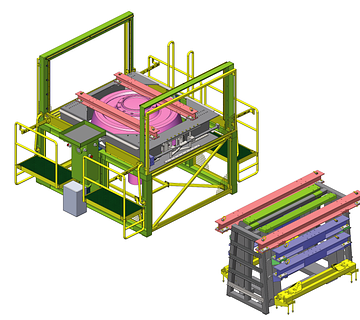

Based on the information gathered, Caden designs a detailed concept. If necessary, we first conduct a preliminary study of a machine (or component). In addition to design, we place significant emphasis on aesthetics, user interaction and experience, and sustainability.

A crucial part of the digital design process is creating a fully virtual 3D model of a physical object. Thanks to this digital twin, a component can be simplified in a short time, such as by reducing weight, resulting in a smarter and more cost-effective production process.

The entire assembly is done in our own "makerspace." This often results in the physical construction of a prototype or the first in a series by Caden.

Thanks to extensive experience and deep knowledge of CAD, Caden's engineers are the perfect team to guide and support your innovation journey. Throughout the entire engineering process, Caden places great importance on communication between you as the client and our team.

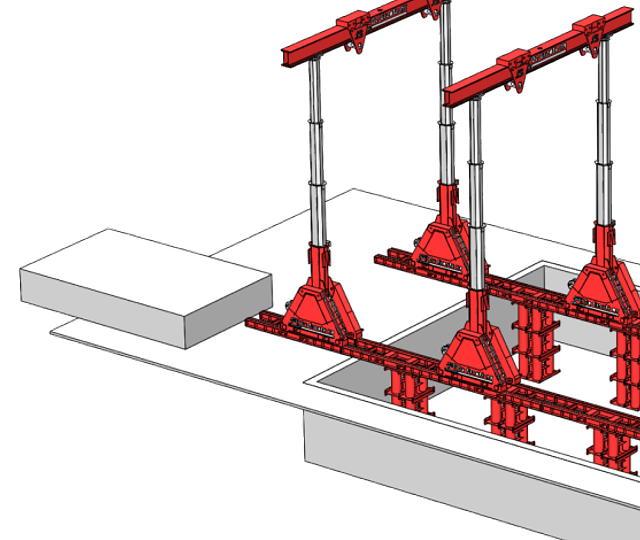

Reverse engineering

Caden analyzes existing machines or components. Measurements or 3D scanning accurately map the machine. Thanks to extensive technical knowledge and CAD expertise, new parts can be produced quickly and precisely.

Measurements are preferably taken with a 3D laser scanner. The results (parts) are correlated both statically and dynamically, and the details are recorded in a digital assembly. This way, the data needed to control 3D printers and CNC machines is obtained.

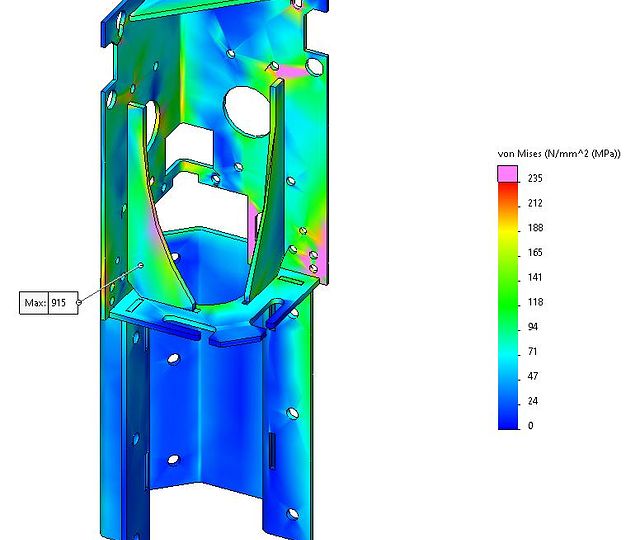

With all this information, components can be tested for strength, material stress, or deformation. They can also be used to create production and assembly drawings.

Caden stores your existing machine in their on-site warehouse for the duration of the engineering process.