Engineering

Vacuum cleaner nozzle

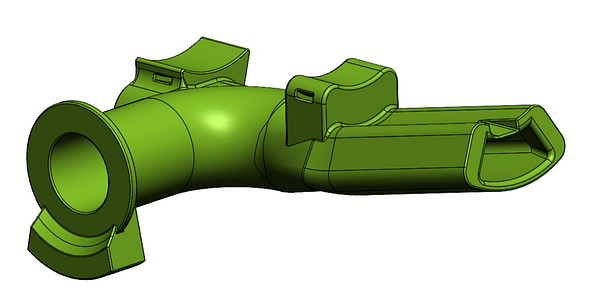

Together with a client from the nuclear sector, we developed an adapter for a vacuum cleaner for use underwater. This vacuum cleaner is used to suction up stainless steel chips generated during the underwater processing, preventing the chips from settling at the bottom of the water bath.

We began by designing the model with the client. Subsequently, various flow simulations were conducted on the design to refine it further before creating a 3D print of the design for prototyping.

Design

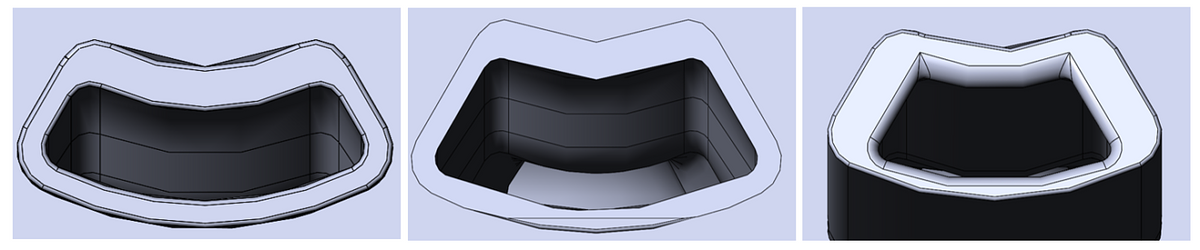

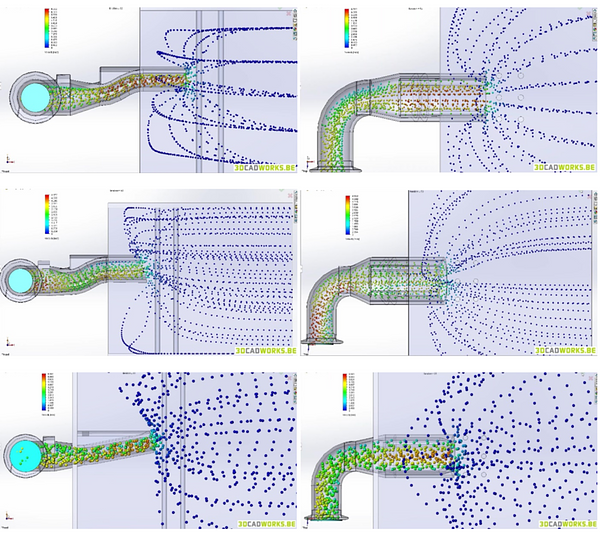

In designing the vacuum cleaner nozzle, we tested several variants using flow simulations to arrive at the optimal model that meets all requirements. One of these design requirements was that the nozzle, with an average suction rate of 25 m³/h, should be capable of picking up both large and small chips, while maintaining a maximum fall speed of 0.2 m/s.

Flow Simulation

Various nozzle openings were developed to achieve the most optimal flow. Each of these openings underwent a flow simulation. The results were compiled into a technical report provided to the client.

Ultimately, a favorable model was obtained that will suction the chips with an airflow speed of approximately 4.5 m/s around the processing area, while maintaining a fall speed of the chips at 0.2 m/s.

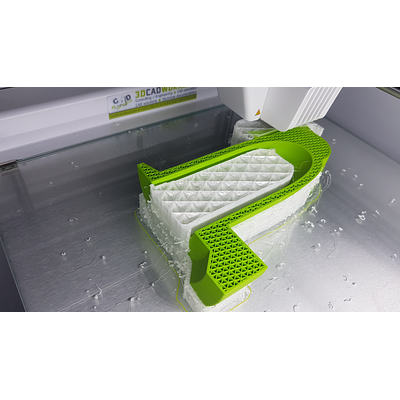

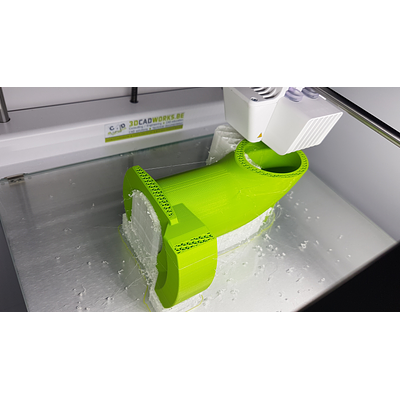

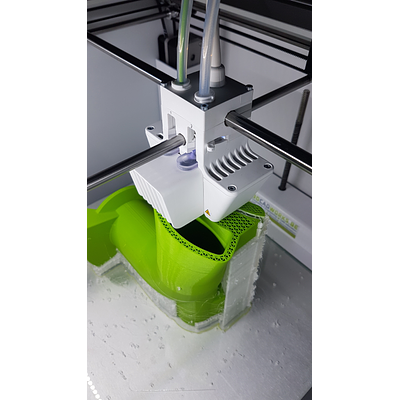

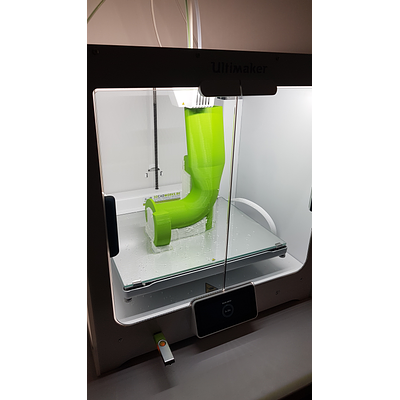

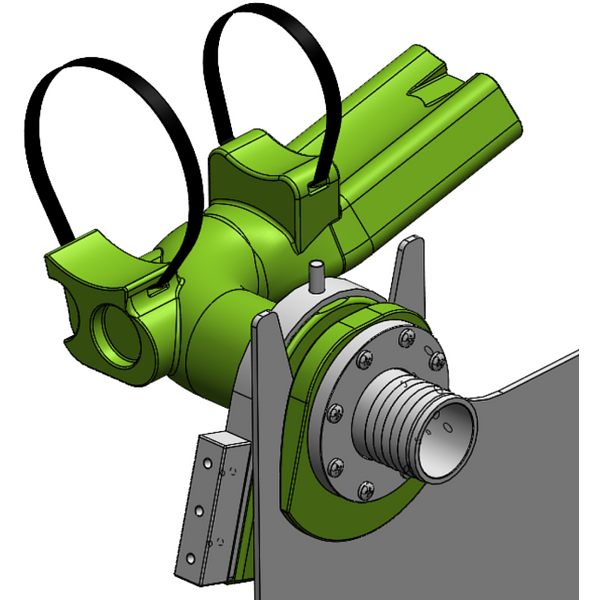

3D Print

Due to the complexity of the part, a prototype was made using our 3D printer. This allowed the entire assembly to be tested. The selected model from the flow simulations was externally modified for printability, and additional components were added externally to enable the nozzle to be mounted within the assembly.